What To Do When Walmart Runs Out of Stock

Learn about:

- What steps to follow when your consumables are out of stock

- What to do as a Collect or Prepaid supplier

- Avoiding out-of-stocks before they happen

Whether you’re a big or small-time supplier, organization is everything. Walmart is continually updating its suppliers’ guidelines, so you must have a plan of action to follow when the retailer runs out of stock. While all the regulations can be overwhelming, we’re here to clear the air on what to do when confronting Walmart’s out-of-stock for consumables.

Here are some questions to ask yourself to help understand the Walmart replenishment guidelines when your items are below your instock goals.

Is the item below the on-shelf availability goal?

Is the item below the on-shelf availability goal? Your answer to this question will determine how you should proceed when Walmart runs out of stock. If the fill rate was under 95% during the previous week, you should follow the following steps. If it was above 95%, you can skip these steps and move to the next heading.

Did the out-of-stock item ship In Full this week?

The first question a Walmart supplier should ask when Walmart runs out of stock is whether the consumables shipped In Full during the current week. If the answer is yes, the solution is relatively straightforward.

You’ll need to ensure the fill rate and recovery are on the weekly performance recap. If your answer is no, you’ll need to follow the following steps based on the time frame.

Review the Consumables Fill Rate for the last four weeks

You’ll need to determine how many weeks the out-of-stock consumables’ fill rate has been under 95% to move forward. If the fill rate has been under 95% for less than two weeks, you only need to ensure the fill rate and recovery are on the weekly performance recap, as you did when determining whether the out-of-stock item shipped In Full during the past week.

If the replenishing rate has been under 95% for over two weeks, take the following steps:

- Contact the production team for an estimated delivery date.

- Send an alert email to the replenishment manager with information and recommendations to cover sales.

- Complete the “share of ship” recap and send it to the replenishment manager.

Related Reading: How Do I View My Instocks in Retail Link?

Was the On Time rate under 90% last week?

If the out-of-stock consumables’ fill rate was not below 95%, your next step is to determine whether the On Time rate was under 90% the past week. If the On Time score was below 90%, your next step is determining whether it was prepaid or collect. If the On Time score was above 90%, you can skip these steps and move to the next heading.

Collect orders

For Collect orders, you’ll need to ask whether there was a request for routing for the last four weeks. If there was, determine if the carrier has been 100% On Time for the previous four weeks.

If you answer yes to these questions, the next step is to provide a recap email to the replenishment manager, including a weekly performance recap.

If the answer is no to whether there was a request for routing for the last four weeks, examine the internal process to ensure compliance. Next, ensure the root cause and recovery are on the weekly performance recap.

Prepaid orders

For Prepaid orders, you’d have to follow a more involved series of steps. Start with the following question: Do you have your current lead time settings by lane? If you answer yes, determine if you are receiving orders too late to process them to ship in time. If this answer is also yes, follow these steps:

- Check Retail Link or Slack for order delays.

- Contact EDI at 479-273-8888 to check for EDI times and delays.

- Contact your RM via email for order timing review.

- Provide a recap email to the RM.

If you are not receiving orders too late to process them to ship in time, follow these steps:

-

Will your orders be ready to ship by the end of the last process day?

If the answer is yes, go to step #2. If the answer is no, review the processing time versus performance. -

Are your orders being picked up on-time?

If the answer is yes, move onto step #3. If the answer is no, review your carrier lane performance. -

Review whether orders are delivering on-time per your carrier.

-

Review your carrier lane performance.

-

Does the delivery time vary from the OTIF reporting?

Whether the answer is yes or no, go to step #6. -

Provide a recap email to the replenishment manager.

Did you receive orders to replenish stock last week?

If you did receive orders in the last week in this replenishment scenario, you’d move to the next heading. If you didn’t receive orders in the last week, your next step would be to determine if you’ve received orders this week.

If you answer yes to this question, include a weekly performance recap and expedite the order if possible. If your answer is no, you should email (Subject: Urgent) and immediately call your RM.

Did the traited/valid count change by >5%?

If your traited/valid count change by more than 5%, you can skip these steps and move to the next heading. If you answered yes, take the following steps:

-

Determine whether you have a planned modular update within the next two weeks.

If the answer is yes, go to step #2. If the answer is no, compare valid stores to traited stores and determine whether there was only a validity change. -

Did the traited store count change by more than 5%?

If the answer is yes, go to step #3. If the answer is no, compare valid stores to traited stores and determine whether there was only a validity change. Then go to step #4. -

Include explanation in the weekly recap.

-

Do you have a modular update in the next six weeks?

If you answer yes, go to step #3. If you answer no, go to step #5. -

Email (Subject: Urgent) and call your RM immediately.

Did the out-of-stock item’s demand increase from four weeks ago?

Your answer to whether an item’s demand increased will determine the best course of action in this scenario. If there was no surge in demand for the out-of-stock consumables, asking the following question: Is the point-of-sales forecast off by more than the category threshold?

If the answer is no, you should email your replenishment manager with information about your concerns and findings.

If the demand has increased from four weeks ago, follow these steps:

-

Did supplier-initiated activities impact demand last week?

If the answer is yes, go to step #2. If the answer is no, go to step #3. -

Analyze settings and performance for evaluation and include an explanation in the weekly performance recap.

-

Did Walmart-related activities occur (like a price rollback) that impacted last week’s demand?

If no, go to step #4. If yes, include an explanation in the weekly performance recap. -

Did external demand activities occur (such as a blog post or celebrity endorsement)?

If no, go to step #5. If yes, include an explanation in the weekly performance recap. -

Did the item have pent-up demand from a previous availability issue?

If no, provide a recap email to the replenishment manager, including a weekly performance recap. If yes, include an explanation in the weekly performance recap.

Related Reading: How to Create a Demand Plan in Retail Link

Final thoughts

It’s not surprising many suppliers are unsure how to proceed when Walmart’s consumables inventory is out of stock, especially considering the countless regulations governing what to do in these scenarios.

Whether you’re dealing with health and wellness or other types of consumables, following the guidelines on avoiding out-of-stocks in this article will ensure you can effectively deal with the many out-of-stock scenarios you’ll face as a supplier.

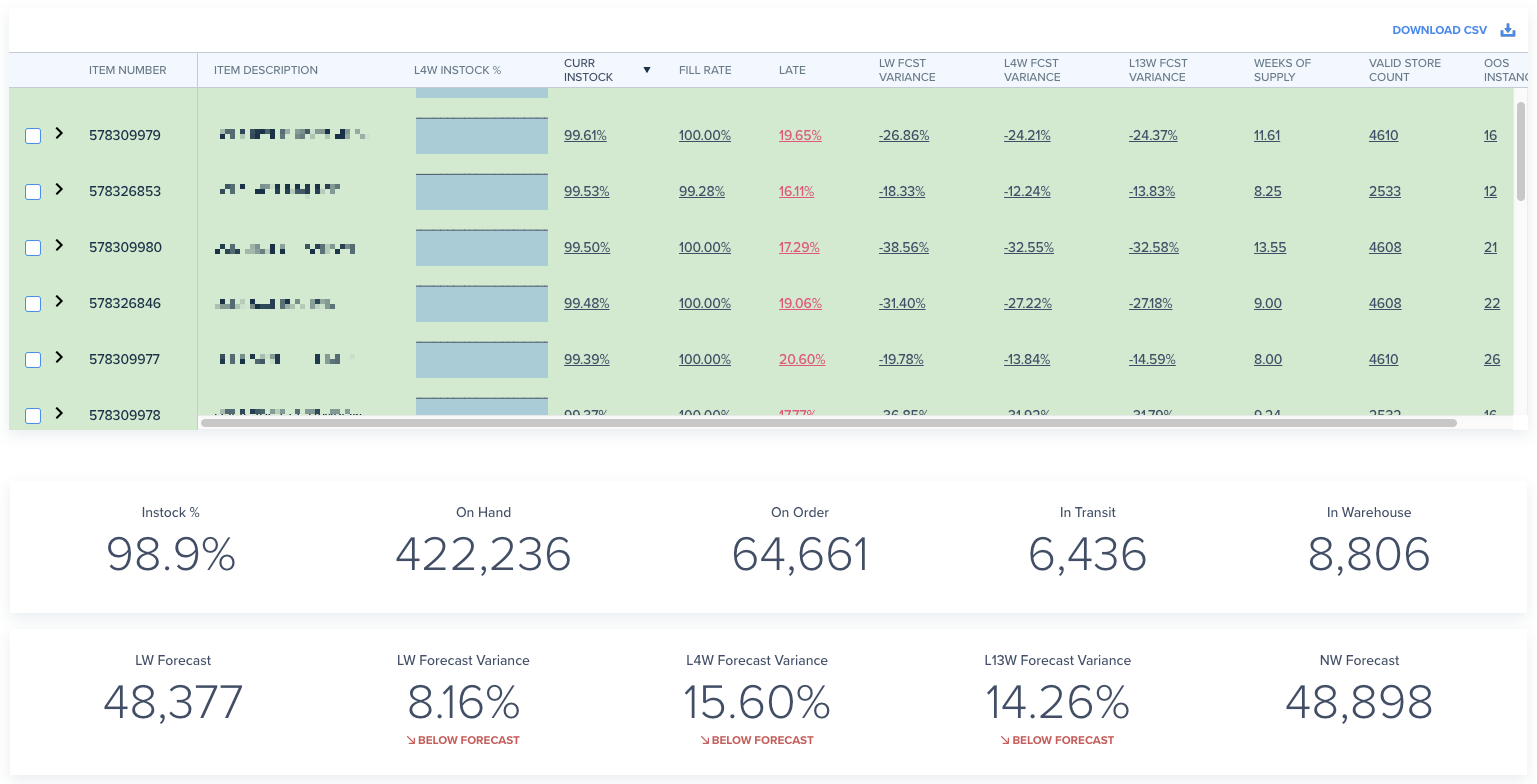

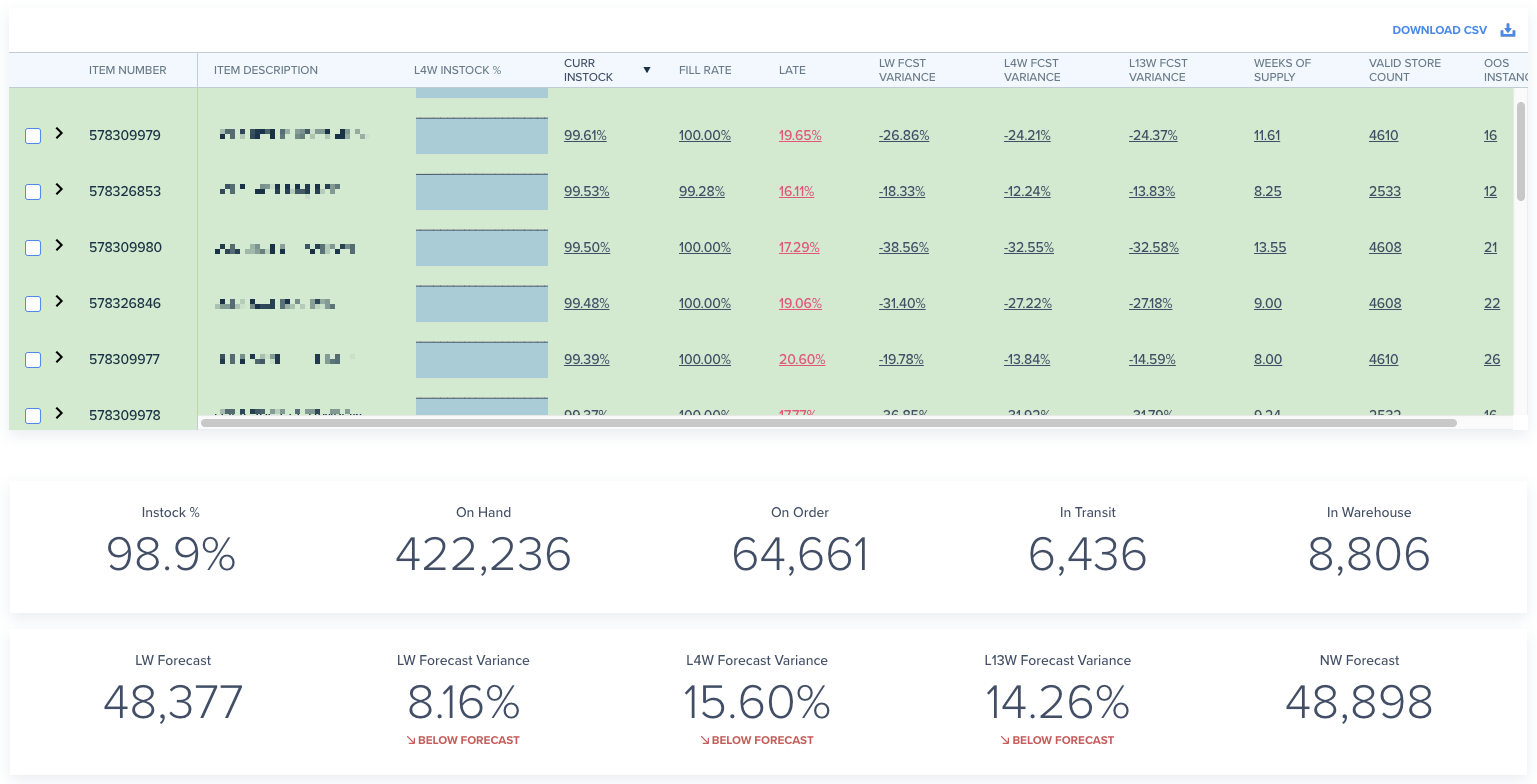

Avoid out-of-stocks before they happen

With SupplyPike’s Retail Intelligence software, harness the power of machine intelligence to predict and curtail out-of-stocks.

Retail Intelligence – Walmart Replenishment

Related Resources

Written by The SupplyPike Team

About The SupplyPike Team

SupplyPike builds software to help retail suppliers fight deductions, meet compliance standards, and dig down to root cause issues in their supply chain.

Read More

About

SupplyPike helps you fight deductions, increase in-stocks, and meet OTIF goals in the built-for-you platform, powered by machine learning.

View SupplyPike's Website