Demand Planning

What Is a Demand Plan?

Demand planning tells you how much inventory you can expect to sell, down to the regional level. Armed with point-of-sales data, knowledge of inventory issues, and accounting for anomalies, you can plan on how much product to manufacture, store in your warehouses, and ship to each region.

Demand planning helps identify potential expansions to your product line or supply, as well as potential threats to your sales. Demand planning helps you cut costs by avoiding things such as overstocks and pricey expedited shipping. With proper demand planning, you can solve problems with your warehouse logistics by predicting how much product should be shipped, where it should be shipped to, and when it should be shipped.

More importantly, your customers require plans to nearly match actual sales. For example, Walmart requires you to be within a 20% error margin between your forecast and your sales before they apply chargebacks. It pays to have a good demand plan!

The Differences Between a Demand Forecast, a Supply Plan, and a Demand Plan

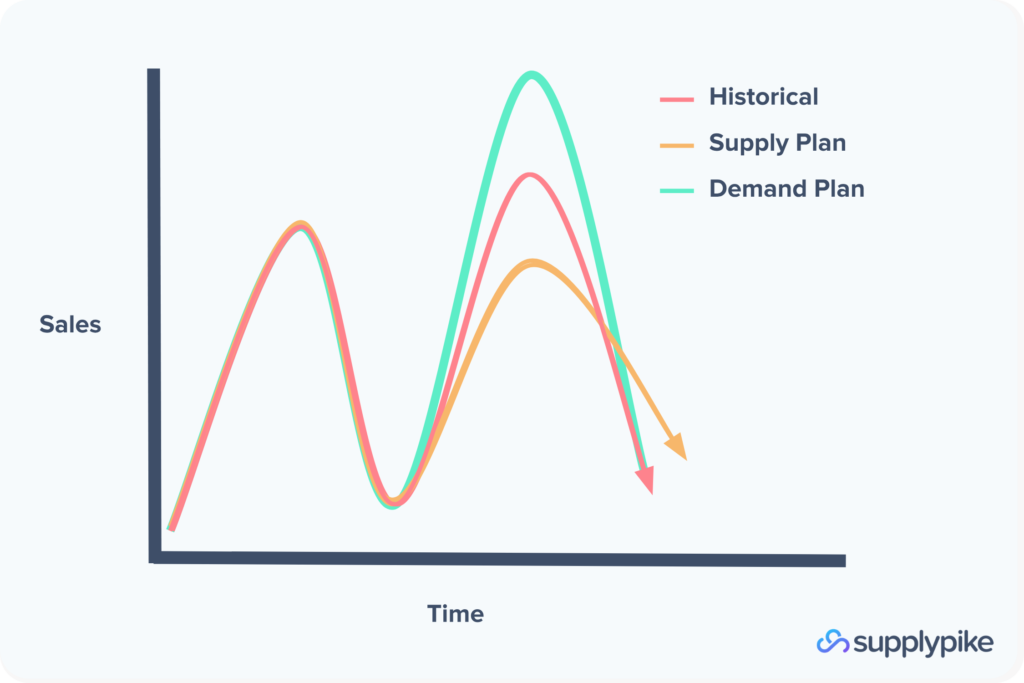

In an ideal world, a demand forecast, a supply plan, and a demand plan would be the same. However, in the complex world of supply chain, there are some key practical differences:

Demand Forecast

Demand forecasts start with historical data to predict how sales will look in the future. This creates your demand forecast model, which represents your past and future sales data. A demand forecast indicates how much each customer expects from you. For Walmart suppliers, this is represented in Retail Link in the Global Replenishment System (GRS).

Supply Plan

A supply plan is used in warehouse and manufacturing settings to determine how much actual product should be created and stored. Supply plans also predict how much product your customers will order from you. These are not based solely on historical sales data, but also take into account seasonal sales highs or lows, discounts, and similar changes.

Demand Plan

Demand plans attempt to tie demand forecasts together with supply plans to create an intuitive, cohesive model. Demand plans are more fluid than demand forecasts or supply plans. They take historical sales data and account for spikes and dips in sales due to variables that you input, such as abnormal weather changes, promotions, viral or guerrilla marketing, and other factors that simple automated point-of-sales analyses cannot identify.

A graphical representation of the differences between a demand forecast (based on historical sales), a supply plan, and a demand plan.

To sum up, a demand forecast asks, “How much does my customer want?” A supply plan asks, “How much product should I make?” And a demand plan seeks to answer both questions, as well as “What should I expect?”

What Is Needed to Create a Demand Plan?

To accurately forecast, you need a historical blueprint of your products and detailed point of sales information broken down by order number, region, season, or any other variable inherent to increasingly complex supply chains. If you are a Walmart supplier, GRS is helpful in determining your future demand, and it also helps understand Walmart’s expectations.

When receiving POS data from a customer, there will generally be a process to clean and standardize the data so that it will reflect expectations more closely. For example, products with different sizes will need to be appropriately grouped, and inner packs will have to be considered in order to calculate actual units.

What Does SupplyPike Offer?

With SupplyPike's software, suppliers can improve the efficiency of their retail products from beginning to end.

Make your Root Cause Analysis count! Don't settle for just winning back money that shouldn't have been lost in the first place. Improve your supplier performance by ironing out the kinks in your supply chain.

Start a free trial today!

Related Resources

Written by The SupplyPike Team

About The SupplyPike Team

SupplyPike builds software to help retail suppliers fight deductions, meet compliance standards, and dig down to root cause issues in their supply chain.

Read More

About

SupplyPike helps you fight deductions, increase in-stocks, and meet OTIF goals in the built-for-you platform, powered by machine learning.

View SupplyPike's Website