What Is Cross-Docking?

Learn about:

- What cross-docking is

- The types of cross-docking

- Who benefits from cross-docking

Cross-docking is useful in reducing waste from storehouses and in the release of capital connected with inventory management. Cross-docking works by reducing inventory in warehouses or moving stock more quickly. Additionally, it allows suppliers to categorize and process orders better and increases product inflow.

What is cross-docking?

The process of cross-docking encompasses the delivery of products directly to the consumer by skipping the process of handling between production facilities.

Cross-docking also reduces the management of materials within the warehouse. Suppliers may assign dispatched commodities to outbound freight from the production zone to the loading ramp.

With the help of cross-docking, suppliers can quicken shipping, meaning consumers receive their orders as and when they select them, building an integrated supply chain. However, there are risks associated with cross-docking that suppliers must account for before switching.

The benefits of cross-docking include reducing labor costs as the warehouse no longer picks the product. Orders come directly from the production facility to the customer. This direct shipping method results in more satisfied consumers and minimizes the need for storage.

Types of cross-docking

There are many cross-docking categories available for warehouse facilities depending on the type of product sent.

- Transport cross-docking: Transport cross-docking blends shipping from various Less-Than-Truckload (LTL) carriers and small-package loads to increase scale economy.

- Cross-docking production: Cross-docking production is the receipt of commodities sold and inbound needed for manufacturing. The warehouse receives the goods and organizes the sub-assemblies for the production orders.

- Supplier cross-docking: Supplier cross-docking unites inbound commodities from numerous vendors into a compound product pallet for transportation to the consumer as soon as the warehouse receives the initial item. For example, computer peripheral suppliers can receive their products from various vendors or put them together in a single shipment for the customer.

- Opportunistic cross-docking: Some warehouses adopt opportunistic cross-docking. The warehouse moves commodities straightaway from the receiving dock to an outbound consignment dock to fulfill the consumer’s order.

- Retail cross-docking: Retail cross-docking comprises acquiring products from different manufacturers or classifying them for multiple retail establishments on outgoing carriers.

How cross-docking works

How exactly does cross-docking function? A truck, aircraft, or another type of carrier typically moves commodities to a retailer. The manufacturer allocates the products and keeps them in storage before shipment.

With cross-docking, suppliers ship via truck, ocean vessel, or airplane and then repack or load the order onto a different means of transportation to the destination. The aim is to transfer the items using the least storage and handling.

Benefits of cross-docking

Many of the benefits of cross-docking are:

- Cost benefits: Cross-docking has the advantage of reduced cost as it reduces product space. Lowering occupancy reduces selection and packaging costs, along with the examination of the commodities.

- Efficiency: Cross-docking is more efficient as it streamlined the loading operation for shorter turnaround times. This operation results in more customer satisfaction and builds an advantage over competitors by meeting consumers’ high demand for more secure and reliable shipping.

- Curtail stockpile management: Cross-docking brings down the time utilized in managing inventory. Shorter times means more time for other activities and economizes productivity.

Disadvantages of cross-docking

However, there are some downsides to cross-docking, such as:

- Capital funding: A substantial initial contribution is necessary to create a capable cross-docking process. Though suppliers will see reduced costs over time, establishing cross-dock ports is a costly affair.

- Highly time-consuming process: Cross-docking can take a considerable amount of time if the process lacks planning, programming, or implementation. Even though incoming commodities swiftly move to an outward bound vehicle, there is a minimum turnaround time. Cross-docking operations must be capable of shipping goods in and out in just a few hours.

- Several carriers: Cross-docking operations necessitate multiple transportation carriers to supply the dock in and out. Multiple carriers may mean increased costs and lower efficiency.

- Survives on suppliers’ faith: Cross-docking depends upon the “just-in-time” manufacturing or shipping school of thought. If suppliers consistently fail to deliver the appropriate commodities or quantities, it hinders the supplier’s ability to meet the customer’s demands, thereby weakening customer confidence.

- Chances of mismanagement: If the supplier does not apply the processes appropriately throughout cross-docking, there are chances of theft and damage due to mismanagement or decreased focus on material management.

Who should use cross-docking

As mentioned earlier, cross-docking is a costly affair even though the benefits are rich. Since its implementation can prove to be exorbitant, it is crucial to understand whether this strategy is beneficial.

For some businesses, the gains are more evident as compared to others who also have adopted cross-docking.

- Stable demand items: Suppliers can apply cross-docking to large shipments on a recurring schedule for items with high or stable demand. Household goods, such as window cleaner, and stable goods, such as breakfast cereal, typically do not see fluctuations in demand due to such factors as seasonality or viral marketing.

- Consumable goods: Consumables and items with short or time-sensitive shelf lives are best for cross-docking, as the products may arrive at the retailer or consumer more quickly. As cross-docking eliminates product storage, the customer can receive the order when requested.

- Slow-moving consumer goods: Items with a longer shelf life, such as slow-moving consumer goods, are prime for cross-docking, as consumers typically desire the fast delivery of these products. SMCGs include appliances and furniture, which customers demand on time.

- Discount customers: Discount retailers typically do not carry all items in stock at all times, and consumers do not expect this inventory to be always available. Cross-docking allows for shipping bulk orders with a variety of products, thus eliminating out-of-stocks.

- Motor vehicles: Conventional automobile suppliers depend on still-in-time delivery and have now been running cross-docking for years. Toyota made the process improvement model famous, creating the [”Toyota Production System.”](https://global.toyota/en/company/vision-and-philosophy/production-system/#:~:text=The%20Toyota%20Production%20System%20(TPS,concept%2C%20in%20which%20each%20process)

- Catering and restaurants: Eateries must have an uninterrupted provision of ingredients, and the deterioration of inventory makes cross-docking a smart option. Businesses are likely to transfer edibles speedily using the supply chain, rather than splurging money on expensive climate-controlled management of stockpiles.

Tracking your inventory

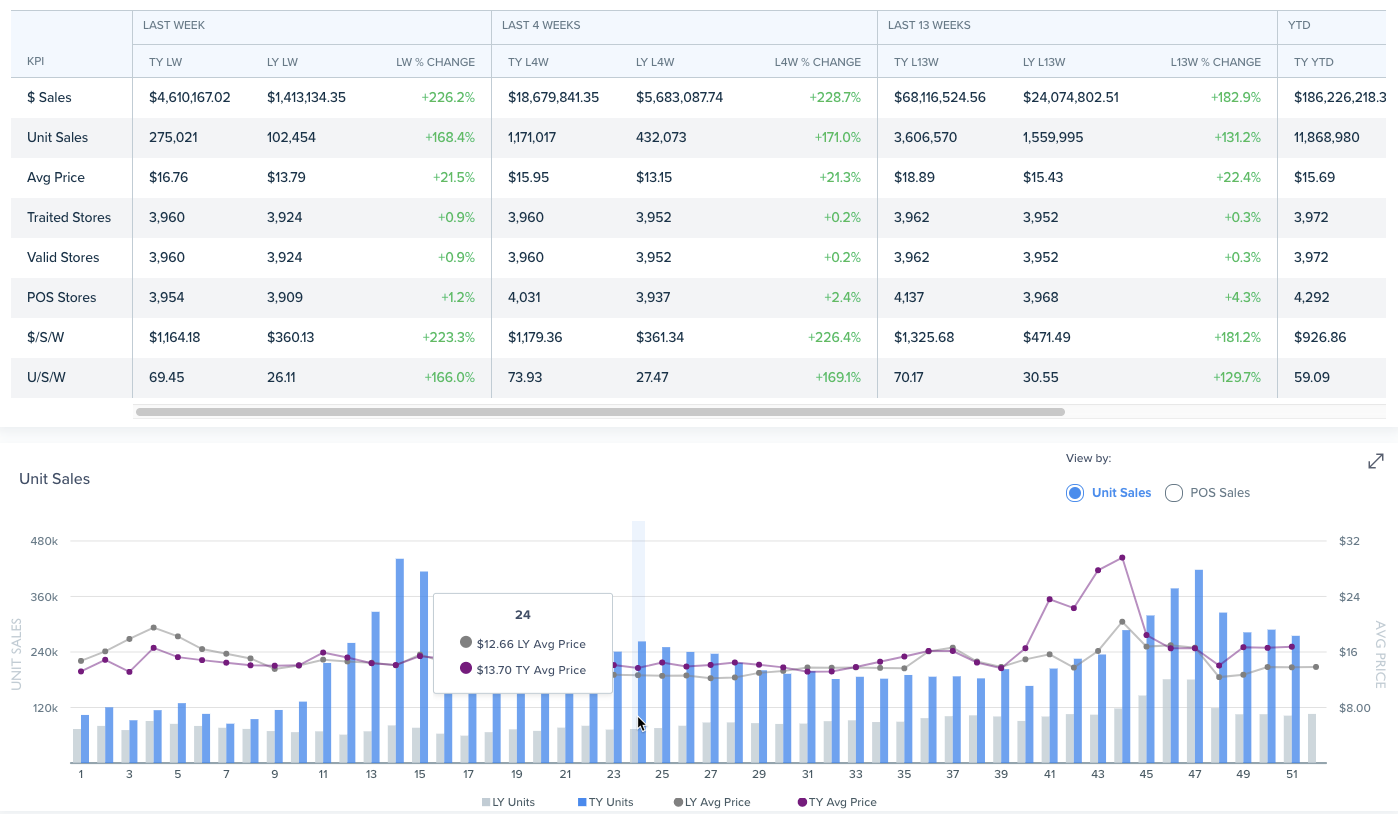

By using SupplyPike’s Retail Intelligence app, you can track your inventory and find out if cross-docking is right for you. Metrics such as the Performance Report can show you how your items are faring at different stores YOY.

Retail Intelligence – Performance Report

And you can get started today for free!

Related Resources

Written by The SupplyPike Team

About The SupplyPike Team

SupplyPike builds software to help retail suppliers fight deductions, meet compliance standards, and dig down to root cause issues in their supply chain.

Read More

About

SupplyPike helps you fight deductions, increase in-stocks, and meet OTIF goals in the built-for-you platform, powered by machine learning.

View SupplyPike's Website