What Are the Different Segments of a Barcode?

Learn about:

- What a barcode is

- How barcodes are used

- The segments of a barcode

People who work in logistics and retail often need to understand barcode segments to ensure packages and inventory get where they need to go. Barcodes have become the standard across any industry that needs to track orders and shipped goods. The anatomy of a barcode includes unique groupings for vital logistical functions.

What is a barcode?

A barcode is a label with parallel bars and spaces. Machines read the barcode segments to assign value to the label. The most predictable place to see barcodes is at retail stores, where nearly all items have them for optical scanning in the checkout lane.

How are barcodes used?

Along with retail stores, barcodes appear in warehouses and distribution centers, on mail or packaging, in libraries, and on invoices. Many states put them on identification cards and driver’s licenses.

Using barcodes makes maintaining inventory and recording sales more accurate than doing so manually. Barcodes create immediate data with exact inventory control.

Because barcodes are so easy to use, employees who utilize them require minimal training, making them cost-efficient. Upfront implementation costs are affordable and have quick returns on investment. Suppliers use the Serial Shipping Container Code (SSCC) in logistics, which contains several vital segments.

What is the anatomy of a barcode?

The anatomy of a barcode varies based on its purpose. For example, retailers have different barcodes for individual items. These codes include vendor information as well as numbers for color, size, and manufacturing date. Packing and shipping companies use the GTIN-14 (Global Trade Item Number) to identify and track items that move in and out of warehouses and distribution centers.

Retailers and vendors use UPCs (Universal Product Codes) on individual items as well as large boxes. Businesses need to get a company prefix from their local GS1 office to maintain standards. Then, they must use that prefix along with item codes on each UPC label.

Barcodes usually have “quiet spaces” to the left and right of the code segments. These quiet spaces help scanners find the code and understand the barcode segments. The anatomy of a barcode includes several essential features that help maintain inventory and create accuracy with package delivery.

These features are:

- Start code-C/function code

- Application identifier

- Shipping container type

- Manufacturer identification number

- Shipping container serial number

- Check digits (CI and CD)

- Stop character

Start code-C/function code

The beginning segment of a barcode is the start code on a shipping container. It includes two non-data characters, then a function code. Label generation equipment automatically inserts the code before adding encoded numeric data.

Application identifier

Barcodes include a prefix that defines the data fields. Employees can read the codes without a scanner. The prefixes name the meaning and formatting for the data that follows it. In the SSCC code, the common application identifier is 00. The printer usually puts the application identifier in parentheses, which is not in the encoded data.

Shipping container type

The next group of numbers is the shipping container type, which shows if the container is a single shipping carton or a large pallet. Often the number is either zero or one.

Manufacturer identification number

Each manufacturer has a unique number in the seven-digit field called the manufacturing identification number. Usually, it has only six digits, with a zero in the first place of the seven-digit field.

Shipping container serial number

The shipping container serial number is a nine-digit number from 000000000 to 999999999 and identifies a shipping container for one year. Logistics departments can identify individual containers and what is inside them, which helps them determine where items are at any time.

On Electronic Data Interchange (EDI) documents, shipping containers can have more than the nine-digit identifier for Advanced Shipment Notice. The containers have 17-digit ID numbers, including the shipping container type, manufacturer’s ID, and shipping container identification number.

The supplier creates and adds the number to the container. Suppliers must use the number for at least one year to accurately track the container and its contents.

Related Reading: SQEP e-commerce Packaging and Labeling

Check digits (CD and CI)

The check digits barcode segment includes two digits, 10 and 103. These modulus numbers help with data integrity when humans read them rather than scanners. The 10 check character has to be before the 103 check character. The check digit verifies that the rest of the barcode is correct. It is usually on the far right side of the barcode.

Check digits exist in other codes. Some businesses calculate the check digit after adding up the rest of the numbers. Others use a scanning system to be sure the barcode is accurate. Suppliers can use a calculator to determine the accuracy of the barcode.

Stop character

A non-data character called a stop character informs the scanner that the barcode is complete.

Barcode segments on UPC label

Coupons usually have a UPC label to help shoppers move through the checkout line. These barcode segments are shorter than those on the SSCC and GTIN-14 labels. For example, each coupon has quiet segments, so the scanner knows where the code begins and ends. On the far left, the code has a coupon number system character (NSC), then a manufacturer’s number with five numerals.

After the manufacturer’s number, the family code and value code comprise the next five digits. The final number is the check digit, which the system calculates automatically before printing.

On a retail tag, the UPC label has slightly different segments. The first digits are the company’s number and can have six to twelve numbers. The next segment contains the product number, which can be two to five numbers. The final number is the check digit. UPCs generally have 12 numbers, and they include the company prefix and the check digit.

Getting a company code

Companies cannot make up their unique UPC numbers, although they can print their own UPC labels. Before making the labels, they must have their unique company code from the GS1, the global standards organization. Following that, they can use their choice of numbers for the product codes they use.

The bars on the label help the scanners identify different data points. The printed numbers are strictly for human eyes to read if the scanners are not working properly.

Track your products

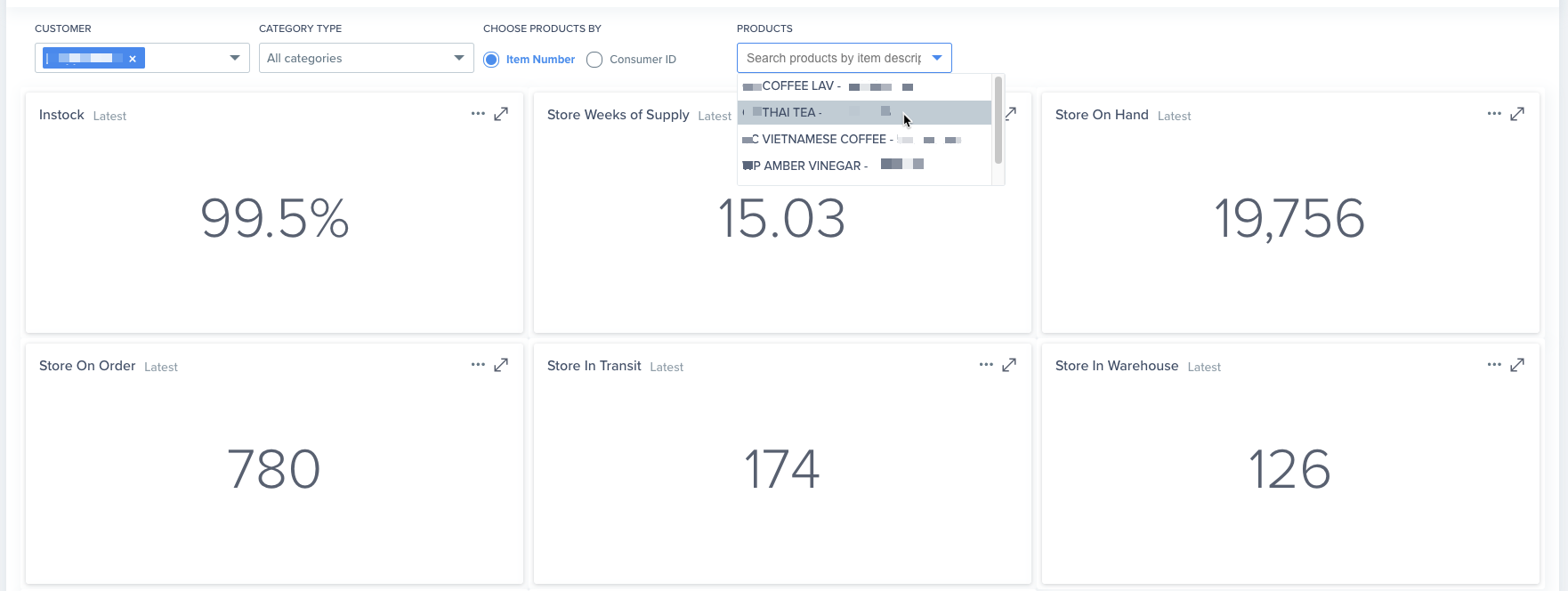

With SupplyPike’s Retail Intelligence software, you can track individual products’ instocks and weeks of supply. View your products’ supply chain with easy-to-digest metrics and dashboards.

Retail Intelligence – Walmart Inventory

See your data in action today for free!

Related Resources

Written by The SupplyPike Team

About The SupplyPike Team

SupplyPike builds software to help retail suppliers fight deductions, meet compliance standards, and dig down to root cause issues in their supply chain.

Read More

About

SupplyPike helps you fight deductions, increase in-stocks, and meet OTIF goals in the built-for-you platform, powered by machine learning.

View SupplyPike's Website